EGR cooler production quality assurance

Advanced assemble line

We introduced the most advanced Korean full-automatic production line, which is a high intelligent assemble line system that monitors each procedure. It alarms automatically even it is an artificial misoperation by accident.

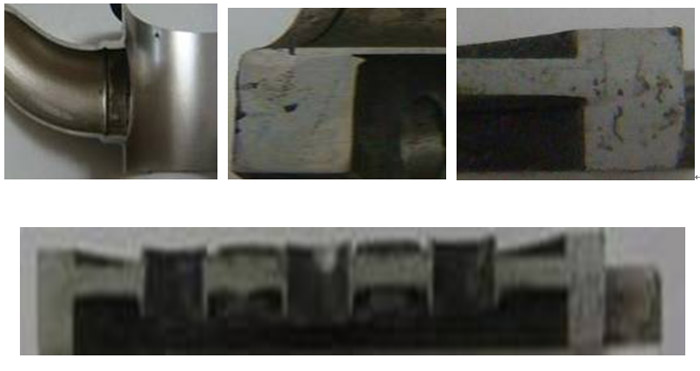

The welding is accomplished by computerized full-automatic system in high quality with clear color, no cracks, low deformation rate, stable and uniform weld formation, excellent performances of welding seam dynamics. It can weld many parts at same time, braze different metals, braze the adjacent several welding lines in one time and braze several components in the same furnace. Other welding methods are not comparable to this system. The reliable welding quality can meet the requirements of high performance welding products from customers. See below vertical section diagram of welding seam:

welding macrostructure

welding seam metallographic microstructure

The advanced facilities ensure the product quality of RICHLEO extremely and fully meet the customer¡¯s requirements. We sincerely expect to cooperate with you to develop for a brilliant future together.

High-precision ATEQ leakage inspection equipment

The high temperature brazed coolers are 100% inspected by ATEQ leakage inspection equipment. The high automatic inspection tool is newly developed by R&D department. ?The inspection is carried out by the equipment automatically after placing the cooler on the tool. The inspection data is recorded by the system automatically after pass the inspection with a unique serial no. for product tracing. The system alarms automatically and separates the unqualified products if any failure products to avoid any confusion.

Quality consistence of EGR valve

Neat and trim production line is lined up according to the production procedures under the method of lean production. Eliminate the waste thoroughly and manage the required objects according to the ¡°5S¡± management principle to save time and power and improve efficiency. Quality control points at key positions are taken care of by persons to ensure the quality.

Monitor the quality control points by imported equipment

Monitor the quality control point: We introduced the special sophiscated test equipment based on our understanding to the Mitsubishi EGR valve and the advantage of test equipment of the Mitsubishi EGR valve after the technical communication with Japanese experts of Mitsubishi EGR valve.

The core of the equipment is a special processor to accomplish measurement automatically. It is adjustable to the parameters of pressure, time etc.

It is used to compare the standard sample with the products to analyze the difference with high accuracy and thus keep the consistence of the product quality.

Key parts in first-grade quality

Diaphragm is the critical part of the minus pressure EGR valve. Demotic factories adopt the normal fluorine rubber diaphragm with poor tensile strength and ductility. RICHLEO adopt the cloth-base fluorine rubber diaphragm from the supplier of Mitsubishi. The price is more than ten times to the normal diaphragm but with 2 times higher resistance to high temperature and same service life as the machine body.

Strictly quality controls to ensure reliable products that are popular with customer.

A. The inspection of critical parts of EGR valve is responsible by the well experienced persons over 100% of the products

B. Irregular high temperature endurance test to EGR valve by random sampling according to the inspection standard and specification. The test results show that the service life of our EGR valve is the as long as the machine body

C. Our EGR valve serials have been inspected by authority department after assembled. The test results all met Euro ¢ó emission standard.