Brazing plate heat exchanger

Structure principle of brazed plate heat exchanger

Our brazed plate heat exchanger use copper as solder and is composed by rotating the corrugated passage plates at 180 degrees. It is brazed by high temperature in the high vacuum brazing furnace to connect the adjacent stainless steel corrugated plates. Each contact point between the corrugated passage plate and filler solder forms the small welding point which forms the complicated cool-heat medium distribution passages. The fine-grained welding points and the edge are brazed by copper so as to ensure the medium of both sides separate from the outside completely. The cold and warm mediums are separated to the two sides of corrugated plate, approaching but not mixing. The Angular holes on the edge make the two mediums form the interactive convective flow. When they flows, heat energy transfers from one medium to another based on the principle of heat transferring, by which it realizes the heat exchange.

As the plate heat exchanger adopts the special design of diverging, it makes the liquid flow distribute uniformly on the whole plate surface and makes full use of the whole heat area. It has features of efficient heat exchange, high heat energy utilization rate, energy saving and environmental-friendly. It is widely used in many fields like industries and agriculture etc.

the principle diagram of brazing plate heat exchanger ]

the features of brazing plate heat exchanger

|

features

|

advantages

|

customer benefits

|

|

Plates one-punch shaping |

1. The depth of corrugation on the same plate is the same, thus ensure each comtact point connect perfectly between the plates.

2. It has no transitional punch area and recessive crack.(the cracks only can be observed by the microscope)

3. The depth of the metal grains is the same on the plate.

4. The thinnest plate reaches 0.3 millimeter..

|

1.The endurance of the plate is improved to avoid stress fatigue and mechanical fatigue of oscillation and high frequency tremble.

2. The mechanical performance is better to avoid the leakage caused by the recessive crack.

3 The contact points distribute uniformly to? form turbulence medium flow for higher heat exchanging efficiency to the limit

4. Lighten the equipment. It has higher heat exchanging coefficient with total heat exchanging coefficient over 2500kcal/m2¡¤H¡¤C. The heat exchanging efficiency is 2 to 3 times of the tubular heat exchanger.

|

|

Patent design of? chocolate ?diverging plate |

1. It can distribute the flow uniformly to the each corners of plate even on the widest plate.

2. Minimize the pressure loss of diverging area.

|

1.All the heat exchanging area on the plate involve in high efficient heat exchanging. All the physical area become the effective heat exchanging area without dead zone.

3 No flow dead zone and anti dirt accumulation to avoid chlorine ion corrosion caused by dirt.

3. Make full use of the permitted pressure drop to improve the flow speed of heat exchanging area and the whole heat exchanging efficiency.

|

|

Unique corrugation angle

|

1. Computer model design according to the real operating condition of the customers for optimal combination of plates.

2 Heat exchanging coefficient is high, liquid holdup is little.

|

1. The optimal combination of plates improves the heat exchanging coefficient ?and reduces the equipment cost.

2. High heat exchanging rate and it make full use of heat energy and reduce energy cost.

|

|

structure compact, integrated volume |

1. Energy-saving, environmental-friendly, safe and low cost.

2. High corrosion resistance, applicable in ?work condition of high pressure and temperature

3. High temperature (400 centigrade) and high pressure(30bar) bearable

4. High material utilization rate. It uses plate to replace tube at lower cost. The complete plate rolling ensure the quality of plate heat exchanger

|

1. Tube replace easily.

2. Easier install and maintain

3. Save huge space for customer and less heat loss.

|

|

High performance

|

Operation and practical technology experience in the heat exchange field for years make this brazed plate heat exchanger reaches to the highest level ?in the counterparts at home.

|

3 years of warranty and 50 years of service life

|

application area of brazing plate heat exchanger

Brazed plate heat exchanger is widely used in the fields of metallurgy, petroleum, chemical industry, foodstuff, pharmacy, shipping, textile and paper making etc. and is the perfect equipment for heating, cooling, heat recovering and short-time pasteurization.

Brazed plate heat exchanger can use the below fluid mediums:

All kinds of coolants, fluids with PH value rather high or low

Organism solutions

Water-oil

All brine solutions (ethylene glycol, calcium dichloride, ethyl alcohol etc. )

RICHLEO brazed plate heat exchanger can be used in below machines:

Heat bump

Industrial ice-water machine, plastics shaping injector, welding machine, hydraulic presser and Compressor with circulating oil.

Air-conditioner

Refrigerator

Air drying machine

Water cooling, drinking water, industrial water

Constant temperature cold storage

Heat recuperation, heat recirculation

Boiler system

RICHLEO brazed plate heat exchanger can use in the below equipments:

Evaporator, condenser, super-heater, super-cooler, energy saver, water cooler, cooler etc.

Installation, Caution and Cleanliness:

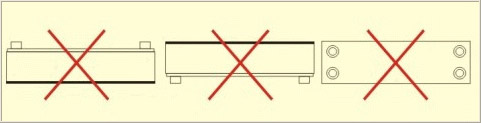

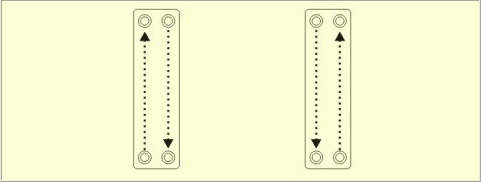

Please install vertically at reverse direction. Do not install horizontally to keep the smallest amount of water below the connection.

Please install vertically at reverse direction for high efficiency of heat exchanging and heat transfer rate.

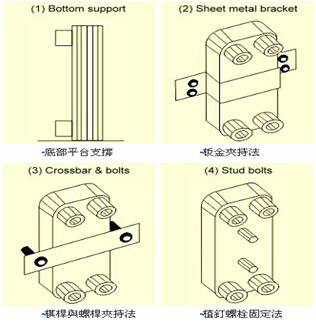

nstall suggestion: 4 installation methods.

Cleanliness and maintenance

Please clean with concentration of 5% weak acid, such as phosphoric acid.

If the liquid is highly acidic, the copper inner the heat exchanger and stainless steel will be corroded.

Use a mass of water wash the inner part of heat exchanger before starting the system to eliminate the residual acid solution.